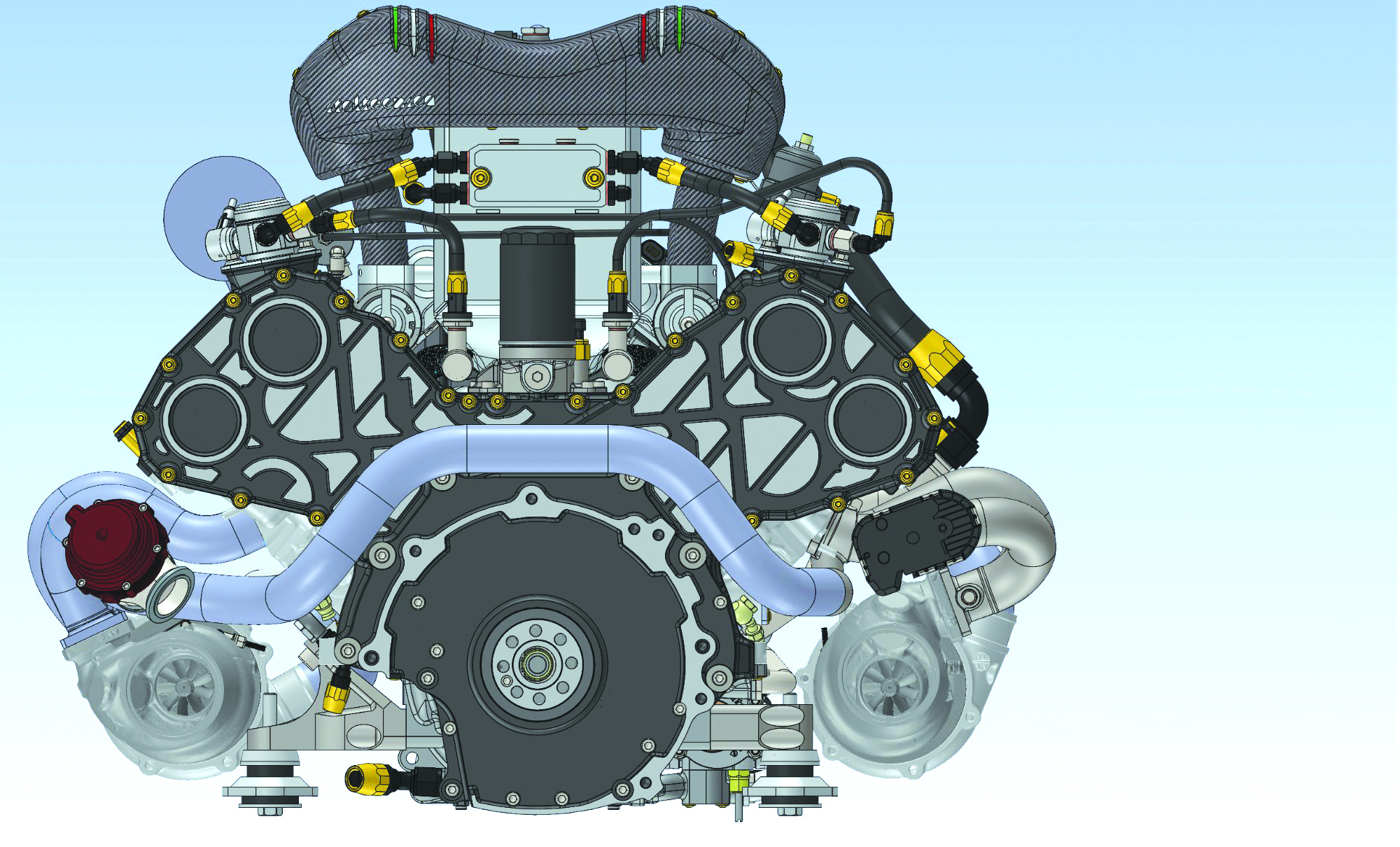

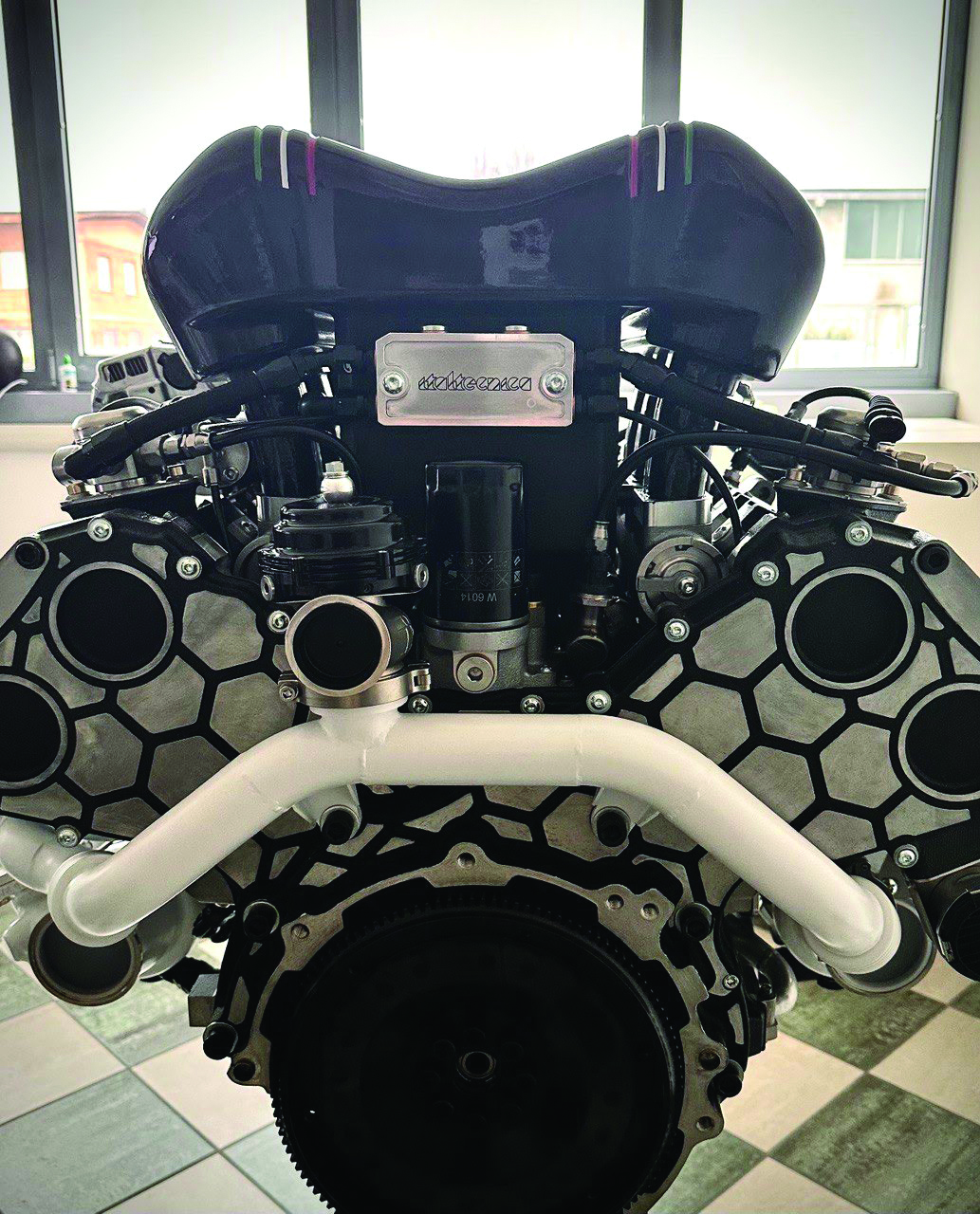

En 2022, Italtecnica, una empresa familiar de construcción de motores con sede en Cambiano, Italia, presentó un V6 secuencial de tres litros y doble turbocompresor con un sistema de combustión de precámara desarrollado internamente. Se están desarrollando dos versiones del motor: una primera variante dirigida a la clase Hypercar de los prototipos de Le Mans, y una segunda iteración destinada al uso en carretera.

Según Carlo Cavagnero, director técnico del proyecto, el motor fue diseñado como muestra de las capacidades de la empresa, con aportes de ingeniería también proporcionados por el departamento de motores de combustión interna del Politecnico di Milano y el supremo de motores italiano Claudio Lombardi, de Ferrari. fama.

“When we started development work with the single-cylinder, we were not aware of this phenomenon and were a little worried. But after we tore the engines down, we could see that all was well and there was no evidence of knock,” Cavagnero says. He also states that both the piston and the combustion chamber have a surface treatment to protect against knock and reduce heat transfer from the combustion chamber.

The engine is still under development and Cavagnero admits that at high-RPM, high-load running, engineers are still establishing whether the combustion is spark initiated or they are into the realms of compression ignition. “We don’t yet understand whether the engine is actually operating in HCCI at high RPM and boost.”

The compression ratio is high for a turbocharged engine; 12:1 to 13:1 versions have been tested with regular pump gasoline, and higher ratios were tested with bioethanol fuel.

Injection strategies

The V6 features port and direct injection systems. Cavagnero explains that this enables the benefits of each to be exploited under different operating conditions and loads. At lower RPM, the control afforded by direct injection enables operation near to the knock limit; however, at higher engine speeds and wide-open throttle, port injection is favored given the limited ability of direct injector technology to provide the required fuel volume.

Outlining how the mixture preparation varies through the engine’s operating range, Cavagnero states that at low RPM there is a very lean, homogeneous mixture in the combustion chamber and a richer mixture within the pre-chamber – around lambda 0.9. Achieving a homogeneous charge is necessary to minimize particulate emissions. At higher RPM, the charge in the combustion chamber remains homogeneous, but within the pre-chamber the mixture is stratified.

The direct injection system still has a role to play at higher RPM. “The direct injector works at higher RPM to fill the pre-chamber,” reveals Cavagnero. “The lambda of the pre-chamber is controlled by the direct injector, but at high RPM the homogeneous charge is achieved with the port injector.”

Another related area of intensive development was the geometry of the piston crown. “Getting this design correct was quite difficult because of the lateral injector spray. You have to ensure it does not spray under the liners, and also you cannot have excessive tumble inside the chamber to keep volumetric efficiency high.” The impact of tumble also had to be balanced against volumetric efficiency at higher operating RPM. While tumble is beneficial to mixture preparation for direct injection, if the effect is too pronounced it can impede volumetric efficiency at high engine speeds. This, reveals Cavagnero, has influenced the design of the inlet manifold (which incorporates throttle barrels), the inlet port and piston crown and the placement of the in-cylinder injector.

Sequential strategy

Key to the concept of Italtecnica’s V6 is the sequential turbocharging setup, deployed to provide low-speed response from the engine (without any hybrid torque fill) while also catering for the not inconsiderable mass flow and boost demand at high RPM. Carlo Cavagnero contrasts this approach to that taken in F1, where engine manufacturers have used increasingly large compressors but with the support of electrical assistance (the MGU-H) to keep response rates low. For Italtecnica, the obvious solution was to use a sequential setup of two smaller turbochargers.

The turbocharging system had to be tailored to support the considerable air demand at high lambda values and the boost pressure required to hit the necessary performance level (670hp in Le Mans Hypercar). To this end, the engine is designed to handle peak combustion pressures of 200 bar that correspond to a simulated peak power equal to 750hpat 8,000rpm.

At lower speeds, below 4,000rpm, only one of the turbochargers is deployed – reducing lag – with two valves: a one-way valve preventing flow being diverted back to the idle turbocharger and an anti-lag valve electronically managed to help spin up the second turbocharger. As engine speed increases, and depending on load, the second turbocharger comes into play in parallel with the first, the transition governed via a closed-loop system controlling the wastegate and the aforementioned valves. The results are impressive. In the roadgoing version, maximum boost is available from 3,000rpm, with maximum torque available from 3,000-6,000rpm, and a peak power of 600bhp. For the racing variant, the torque band moves up to 4,000-6,500rpm with peak power at 8,000rpm.

At time of going to press, Italtecnica is reporting considerable interest in the engine, although most of it is confidential. However, Cavagnero reveals that Totem Automobili, which produces bespoke, carbon-bodied Alfa Giulia restomods, has already taken delivery of two engines, and a total of 12 are due to be supplied by the end of 2024 for fitment in its GT Super models. There is also ongoing development of the pre-chamber ignition system aimed at mainstream automotive.

Vital statistics

Layout: 90°, V6

Induction: Twin, sequential turbocharged. Pre-chamber ignition

Power: 750hp @ 8,000rpm

Fuel: Gasoline

«Emprendedor. Aficionado incurable al twitter. Gamer. Aficionado apasionado de la cerveza. Practicante de la web. Estudiante típico».

También te puede interesar

-

Samsung podría dividir notificaciones y configuraciones rápidas en Android 15

-

Galaxy Z Flip 6, Z Fold 6 y los nuevos wearables de Samsung están a la venta

-

La audiencia reacciona a las nuevas funciones de IA en los dispositivos Galaxy en París – Samsung Global Newsroom

-

Robbie MacDonald nombrado jefe de propiedad de IQUW

-

La teoría cuántica explica las oscilaciones de conductividad de LNL